Researchers in Korea have developed a scaffolding technology for achieving precise marbling patterns in cultivated meat at scale.

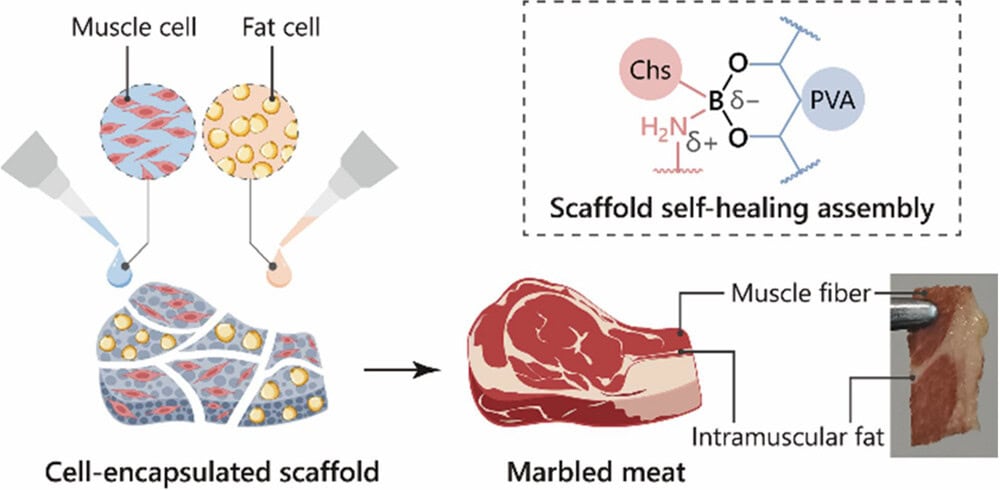

In a new paper, they describe the use of self-healing hydrogels containing boronic acid-conjugated chitosan. This achieves robust reversible bonding at a neutral pH, unlike conventional hydrogels which require nonphysiological conditions for strong, reversible bonding. Each hydrogel variant optimizes mechanotransduction (the conversion of a mechanical stimulus into chemical activity) for the differing requirements of fat and muscle cell culture.

Biocompatibility studies have confirmed that the scaffolding technology supports the growth of mouse-derived cells and bovine-derived primary muscle cells. It reportedly enables the assembly of muscle and fat monocultures into centimeter-thick meat with micrometer-scale marbling patterns. Furthermore, organoleptic and nutritional properties can be adjusted without the need for meat glues or processing equipment.

“Straightforward method for producing marbled meat”

Previously, muscle and fat had to be cultivated separately, impairing the texture of the finished cultivated meat product. But the new scaffolds are said to create a more authentic meat-like appearance and texture, resembling the intricate marbling found in steak. Furthermore, the muscle and fat layers have been observed to have strong adhesion that cannot be easily broken.

The new technology can reportedly be incorporated into existing cultivated meat production lines, and uses relatively affordable raw materials.

“This scaffolding technology enables the simple assembly of a realistic marbled meat prototype from monocultures without the need for cross-linkers or processing devices, and offers a straightforward method for producing marbled meat in vitro with organoleptic properties and nutritional profiles similar to those of conventional meat,” say the researchers.